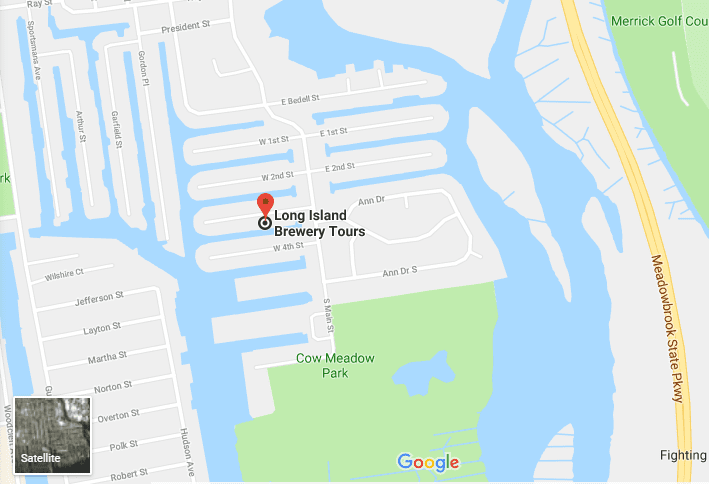

Long Island Brewery Tours

Long Island Brewery Tours is an exciting service offering the opportunity for Tastings and Tours to the outstanding Breweries here in Long Island, NY. Using our Limousines, Limo/Party Buses and our experience in providing quality service, you are sure to enjoy the many wonderful varieties of Beer as you tour the very Best of Long Island Breweries. In addition to running our Beer Tours, we also offer exciting gift packages for any occasion. Holidays, Birthdays, Engagement Parties, Anniversary’s, Fathers Day, Bachelor Parties, Sporting Events, or just a Relaxing Day of Atmosphere, Drinking and Enjoyment. Each and everyday is a great day for a Beer Run.

Long Island Beer Tasting

At the start of your day, you will begin with pickup. Here you will be provided with your itinerary, previously determined based on your individual needs. Our drivers will take you and your party to Long Island Brewery Houses to visit a minimum of two Brewery Pubs. Don’t worry, You’ll relax and enjoy the atmosphere all while tasting the various Beers the Brew Makers offer. Clients can choose to spend the afternoon leisurely tasting beer and speaking to the Brew Masters and/or you can schedule your visits during the Beer Processing where you’ll learn in detail the procedure that creates such exceptional Beer on Long Island.

Not all of the Beer Pubs – Breweries offer food. So you have a few options. You are certainly welcome to bring food with you. Or you can sit down for Lunch at a Brewery but their are very few select breweries that offer food. Please discuss this with your Beer Tour operator. In addition, you can also have dinner based on your scheduled time frame when reserving your Beer Tour. Some Breweries even have live entertainment on a nightly basis. So you might want to extend your stay, have dinner and enjoy the music (prices vary). We will even reserve your seating, leaving you and your guests with only one responsibility, Eat, Drink & Enjoy.

Private Group or Corporate Beer Tours

Remember if you have a small group or a large group, we can accommodate. All of our stretch limousines and party buses are owned and operated by us. We are NOT a broker. Don’t forget we have been in the ground transportation Industry for 19 years. We also offer other tours and Staycation Adventures on Long Island. These Long Island tours include; Wine Tours, Dinner packages, Helicopter Rides in NYC and Christmas Light Tours during the Christmas Holiday. For more information on our Long Island Brewery Tours or to make a reservation please click on this link L I Brewery Tours or call us today at (718)-BEER-TOURS.

Click & Play while YOU Browse our Website